5 Ways to Ensure Precision in Your Manufacturing Processes

In the world of manufacturing, precision is key. Without it, products can go off track, leading to wasted resources and unsatisfied customers. Fortunately, there are ways to ensure precision in your manufacturing processes.

Here are five effective ways to make sure every piece of your production is accurate and efficient.

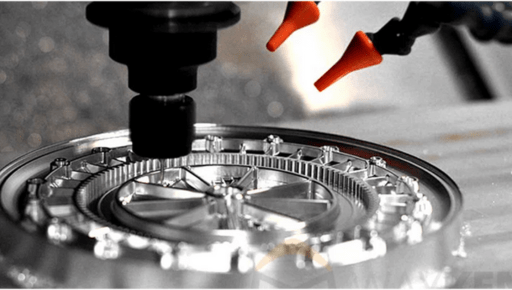

1. Invest in CNC Machining

CNC machining has revolutionized the manufacturing industry by offering high precision and repeatability. CNC, or computer numerical control, refers to machines that are controlled by computers to carry out precise cutting, drilling, and shaping of materials.

By investing in cnc machining, you ensure that every part produced is identical, meeting the exact specifications. The precision offered by CNC machining reduces the chances of human error. With the right settings, these machines can make parts consistently, which leads to higher product quality and less material wastage.

2. Regular Calibration of Equipment

Manufacturing machines need to be calibrated regularly to maintain their precision. If your equipment is out of calibration, even slightly, it can lead to significant errors in your products. Regular calibration helps keep machines running at their best, ensuring that they produce parts to the exact specifications.

This is especially important for tools and machines that are used frequently. Over time, wear and tear can affect their accuracy. By setting up a routine calibration schedule, you can catch any potential issues early, preventing errors and costly rework down the line.

3. Buy High-Quality Hydraulic Pumps

In many manufacturing environments, hydraulic pumps are used to control the flow of fluids and power machinery. These pumps need to be high-quality and precise in their operation. Poor-quality hydraulic pumps can lead to irregular pressures, which can affect the performance of the machines they’re powering.

To ensure precision, it’s vital to Buy Hydraulic Pumps that are reliable and accurate. High-quality pumps maintain consistent flow, pressure, and speed, allowing machines to operate smoothly and with high precision.

4. Focus on Staff Training

Even with the best machines, your employees need to understand how to operate them correctly. Precision isn’t just about the tools you use—it’s about the people who operate them. Well-trained staff can spot potential problems early, adjust machines as needed, and ensure that the manufacturing process runs smoothly.

Investing in employee training and skill development is crucial for maintaining precision in manufacturing. Regular workshops and training sessions ensure that your team stays up to date with the latest techniques and equipment, keeping precision at the forefront.

5. Implement Quality Control Checks

No matter how precise your machinery is or how well-trained your team is, there will always be a chance for mistakes. That’s why implementing quality control checks at every stage of the manufacturing process is essential.

Regular inspections of parts, assembly lines, and final products can help catch issues before they become bigger problems. Quality control also involves testing and measuring the products to ensure they meet the required specifications.

Conclusion

Precision in manufacturing isn’t just about having the best machines—it’s about creating a system where every part of the process is carefully controlled and executed. By investing in CNC machining, regularly calibrating equipment, buying high-quality hydraulic pumps, training your staff, and implementing quality control checks, you can ensure that your products are consistently precise and of the highest quality.